HDO, HSO, HDB, HSB

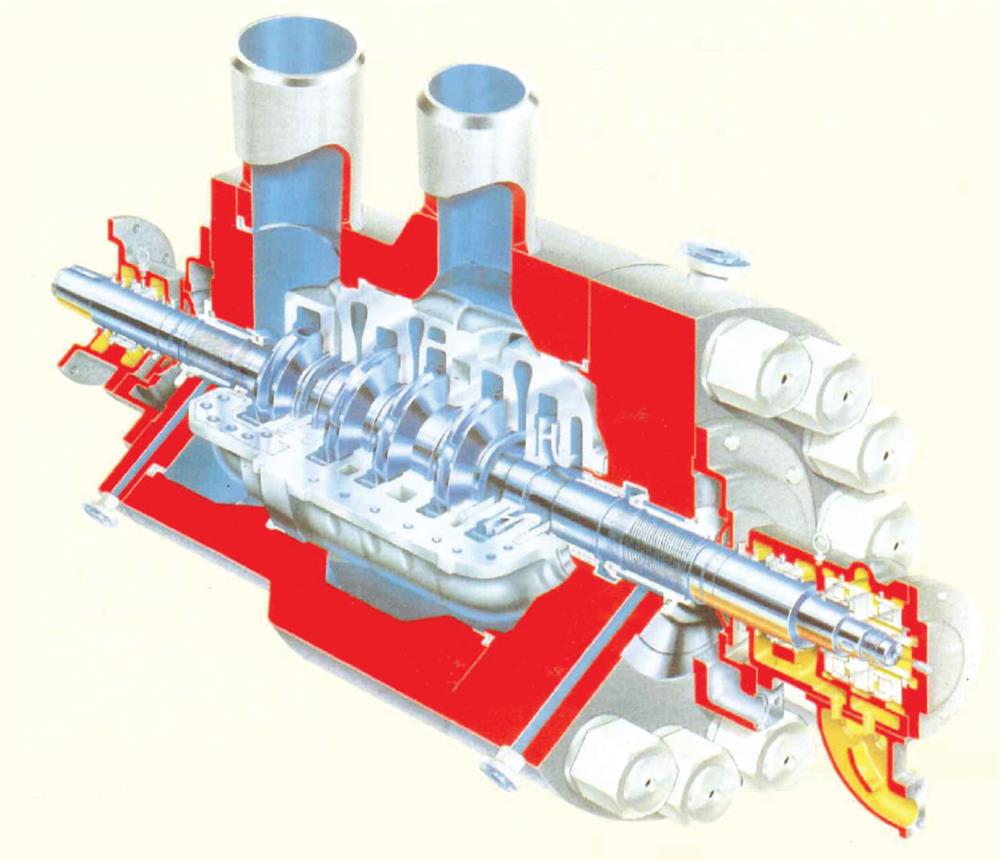

HDO, HDB (double suction, first stage) and HSO, HSB (single suction, first stage) are double casing, multi-stage pumps. An outer barrel and cover with one radial high pressure sealing joint encloses an axially split inner volute casing.HDO an HSO pumps are fully compliant withAPI 610, 8th Edition for petroleum and petrochemical applications.

Applications:

- Process charging

- Hot oil

- Injection

- Pipeline

- Boiler feed

Operating Parameters:

- Temperatures to 800°F (430°C)

- Pressures to 6000 psi (41370 kPa)

- Flows to 18000 gpm (4090 mVh)

- Operating speed to 9000 rpm

Choice of nozzle orientation:

- Top suction, top discharge

- Bottom suction, top discharge

- Side Suction, side discharge

- Other options available to match field piping.

Choice of nozzle connection:

- Weld end

- Flanged

Choice of shaft sealing:

- Throttlr bushings

- Mechanical seals

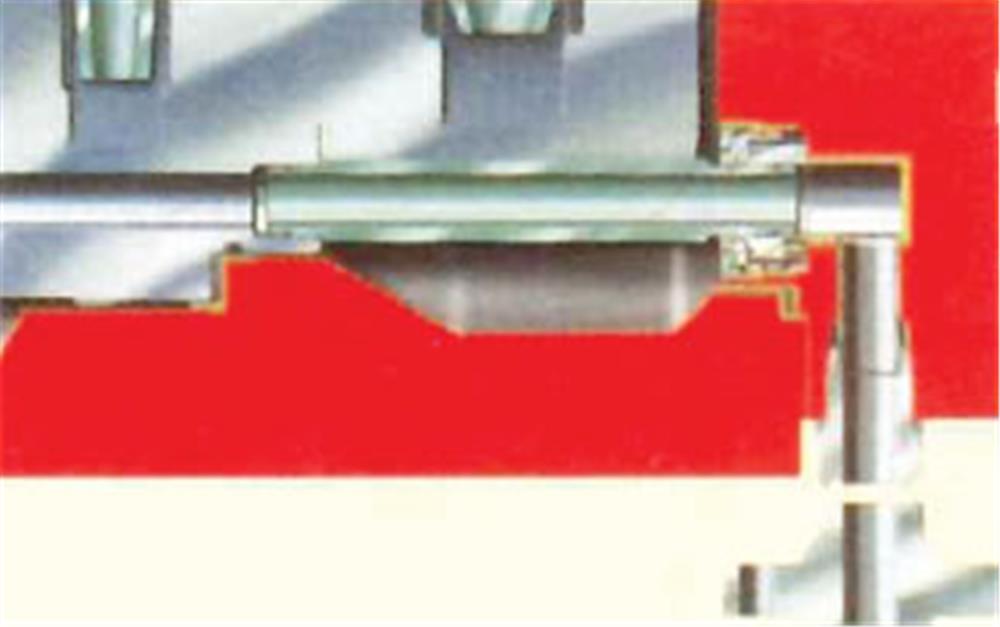

Outer Barrel for high pressure

HDB five-stage with shaft sealing and nozzle arrangement for typical boiler feedwater service

Axially Split Inner Case design allows for dynamic balancing of assembled rotating element prior to installation

Double-Acting, Pivot-Shoe Thrust Bearings and Self Aligning, lubricated Babbit-Lined Radial Bearings are standard, providing maximum reliability and reduced maintenance cost

HDOI, HSOI, HDBI, HSBI

These are compact versions of the HDO, HSO, HDB and HSB pumps incorporate hydraulic innovations in impellar and volute casting designs.